Table of Contents

Get Custom eCommerce Fulfillment Service

Book a Meeting

10 Proven Ways to Reduce Picking and Packing Errors in Your Warehouse

Time: Dec 31,2025 Author: SFC Source: www.sendfromchina.com

It’s no surprise that errors in warehouse picking and packing can be one of the biggest cost drivers in logistics. A mis-picked item means rework, shipping delays, increased labor, diminished customer satisfaction, and lost revenue. For third-party logistics (3PL) providers like SendFromChina, precision isn’t just operational—it’s a competitive advantage.

In this guide, we’ll walk through real-world strategies, process enhancements, and technological tools that reduce mistakes in picking and packing. This isn’t theory alone—we’ll draw from prominent industry insights and applied best practices from warehouses around the globe. Whether you run a single fulfillment center or manage thousands of SKUs across multiple locations, this article will help you minimize errors and increase accuracy.

1. Why Picking and Packing Mistakes Happen

Before diving into solutions, it’s important to understand why mistakes occur in the first place. Often, errors aren’t just about individual worker performance; they’re rooted in systems, processes, layout, and information flow.

Common factors include:

Inefficient warehouse layout — poorly organized storage increases the likelihood of picking the wrong item.

Manual, paper-based methods — without real-time visibility, pickers can follow outdated or incorrect instructions.

Lack of verification steps — if no one checks each step, errors travel down the line to customers.

Insufficient training and inconsistent SOPs — inconsistency breeds mistakes.

Errors at high volume multiply rapidly. Even a 1% error rate in a warehouse processing thousands of orders per day can mean hundreds of wrong shipments weekly.

2. Start with Clear Standard Operating Procedures (SOPs)

At the foundation of any quality picking and packing operation are standardized practices.

Why SOPs Matter

Standard Operating Procedures document exactly how tasks should be performed—step by step. When every team member follows the same, clear procedure, variation and ambiguity are reduced dramatically.

What Good SOPs Include

Detailed task steps for pickers and packers

Handling instructions for fragile or complex items

Barcode usage rules and scanning checkpoints

Illustrations or photos for product identification and packaging standards

Error handling workflows

When SOPs are well documented and regularly updated, new hires get up to speed faster and veteran staff perform with fewer mistakes.

3. Invest in a Robust Warehouse Management System (WMS)

One of the most transformative investments for a warehouse is a strong Warehouse Management System.

What a WMS Does

A WMS provides real-time oversight of inventory and guides employees through picking and packing steps electronically.

Top WMS Benefits

Real-time inventory accuracy — reducing guesswork.

Optimized picking routes — cutting confusion and travel time.

Directed picking and verification — guiding workers with scans and prompts.

Reduced dependency on paper — lowering transcription and manual errors.

With a modern WMS, the system becomes the “truth source” — eliminating mismatches between skylines and actual inventory. This is especially critical for 3PLs handling high SKU counts and dynamic cross-border inventory flows.

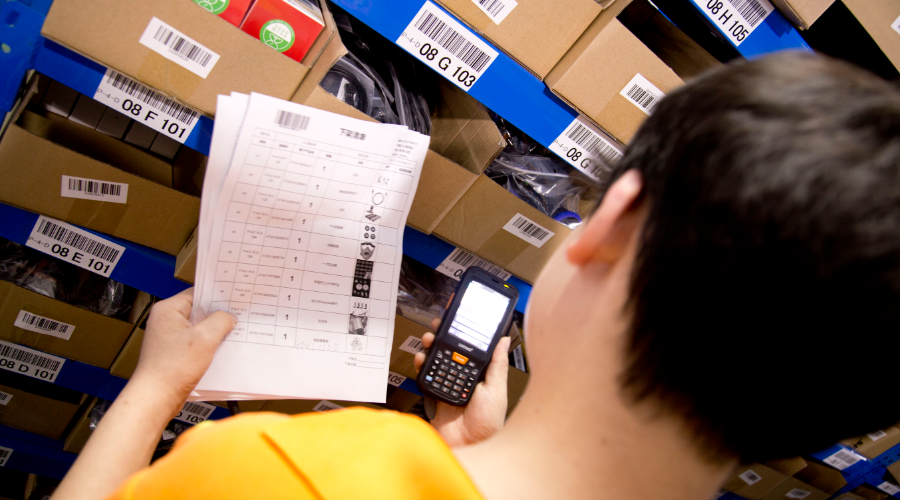

4. Use Barcode and RFID Technology

Automated scanning technologies are among the most reliable ways to catch mistakes before they happen.

Why Barcodes Help

Barcodes and RFID tags transform human memory and sight into a system-verified action. They ensure that the item the worker thinks they are picking is indeed the item the order requires.

Key advantages:

Instant verification of item identity

Reduced dependence on memory or visual cues

Automated inventory updates

Error alerts if something is scanned incorrectly

Barcodes at both the picking and packing stage create built-in checkpoints where the system can stop an incorrect item before it moves forward.

5. Strategically Organize Your Warehouse Layout

Every step in the picking process is influenced by where your products are stored.

Optimize Storage Based on Demand

Use inventory velocity to guide placement:

High-velocity (“A”) items near packing stations

Medium-velocity (“B”) items in easily accessible zones

Low-velocity (“C”) items in less prime locations

This is known as ABC analysis — and it improves efficiency while lowering fatigue-related mistakes.

Logical, Consistent Labelling

Clear aisle, shelf, and bin labels reduce confusion. Complement them with color coding or visual identifiers for quick reference.

Plan Picking Paths

Minimize unnecessary travel and backtracking. When pickers follow defined routes, they’re less likely to skip or mis-read an item’s location.

6. Implement Quality Control Checkpoints

Even the most accurate picking processes may have occasional errors. Tiered quality checks help catch these before they reach your customers.

How Quality Control Works

Verification at picking — scanner prompts confirm quantity and item

Double-scan at packing — ensures correct order before sealing

Final inspection before shipping — a last review of labels and contents

These checkpoints act like filters, capturing mistakes at several stages rather than allowing them to pass through until a customer complains.

7. Standardized Packing Procedures

Packing is where picking accuracy meets customer expectations.

What to Standardize

Box selection guidelines — choose the right size based on dimensions and protection needs.

Protection protocols — how much and what type of packing material to use for various product types.

Checklists for each order type — to ensure nothing is omitted.

Packing errors, like damaged goods or missing promotional inserts, have a direct impact on customer satisfaction, so standardization here is just as important as in picking.

8. Continuous Training and Performance Feedback

Technology and SOPs are valuable, but none of it works without well-trained, engaged staff.

Training Best Practices

Hands-on onboarding — pairing new hires with experienced workers.

Ongoing refreshers — regular sessions on systems, product changes, and SOP updates.

Performance transparency — tracking accuracy metrics and sharing them constructively.

Continual learning fosters a culture of quality and accountability. When employees understand that accuracy is a company priority—not just speed—they often perform better.

9. Adopt Advanced Technologies

Beyond WMS and barcodes, advanced tools are reshaping how warehouses reduce errors.

Voice-Directed Picking

Workers receive spoken instructions and confirm actions verbally or through simple device prompts. This minimizes hands-off distractions and improves focus.

Pick-to-Light & Put-to-Light Systems

Lights at storage points signal exactly where and what to pick. This visually directed method drastically cuts mistakes, especially for high-volume, multi-SKU orders.

Mobile Robots and AGVs

Autonomous Mobile Robots (AMRs) and AGVs can deliver product pods to humans, reducing walking time and mental workload on pickers—both factors that correlate with human error.

10. Analyze and Improve Continuously

Becoming error-proof isn’t a one-time activity—it's continuous improvement.

Use Metrics to Drive Decisions

Track key performance indicators (KPIs) like:

Order accuracy rate

Picking error rate per shift

Average time per pick

Return rate due to fulfillment errors

By analyzing this data, you’ll identify patterns—for example, certain SKUs or times of day with higher errors—and take targeted action.

Root Cause Analysis

Don’t just fix errors—understand why they happened. A short weekly review with the team can illuminate underlying issues before they become systemic.

11. Outsource to 3PL Experts (Like SendFromChina)

For many businesses, partnering with a third-party logistics provider is the fastest way to reduce picking and packing mistakes.

Benefits of Professional 3PL Fulfillment

Established SOPs and trained staff

Technology-driven processes

Scalable accuracy across seasons

Data-driven improvements

3PL providers make error reduction part of their service, not an afterthought. They invest in technology and people so that your customer experience remains consistent and reliable.

12. Conclusion

Reducing picking and packing mistakes isn’t about eliminating humans—it’s about empowering them with systems, tools, and processes that support accuracy. From clear SOPs and modern WMS platforms to barcode scanning and advanced automation, every layer you add to your fulfillment stack is a layer of protection against costly errors.

For businesses operating in the global e-commerce landscape, accuracy in fulfillment is no longer optional—it’s a strategic imperative. Whether you’re improving an existing warehouse or working with a third-party logistics partner like SendFromChina, the strategies above will help you minimize errors, improve customer satisfaction, and drive operational excellence.

13. Frequently Asked Questions

What’s the biggest cause of picking errors in warehouses?

The most common causes are human mistakes due to poor organization, outdated systems, and lack of verification steps.

Does technology really reduce picking mistakes?

Yes—tools like WMS, barcode scanners, and pick-to-light systems dramatically cut errors by automating steps and providing real-time guidance.

How often should warehouses conduct training?

Training should be ongoing with regular refreshers and updates, especially when SOPs or technology change.

Can smaller warehouses afford advanced picking tech?

Many scalable options exist—from mobile scanning devices to cloud-based WMS—that fit smaller operations without huge investments.

Why should I partner with a 3PL for fulfillment accuracy?

3PLs specialize in fulfillment operations and invest in best-in-class tools and training, which can be costly and complex for individual businesses to manage alone.

Post Views:2254

Post Views:2254

Copyright statement: The copyright of this article belongs to the original author. Please indicate the source for reprinting.

Previous Post

The Best Shipping Solutions for Small and Lightweight Ecommerce Products

Next Post

TAGS

Hot Research

Get Custom eCommerce Fulfillment Service

Book a Meeting

Get a Custom China Fulfillment Solution with FREE Storage for 30 Days

Want to know about our services, fees or receive a custom quote?

Want to know about our services, fees or receive a custom quote?

Please fill out the form on the right and we will get back to you within a business day.

Please fill out the form on the right and we will get back to you within a business day.

The more information you provide, the better our initial response

will be.

The more information you provide, the better our initial response

will be.

TAGS:

TAGS: