Table of Contents

Get Custom eCommerce Fulfillment Service

Book a Meeting

How Do I Organize My Warehouse Layout

Time: Apr 25,2023 Author: SFC Source: www.sendfromchina.com

I. What Is Warehouse Layout

Warehouse layout refers to the arrangement of different areas and zones within a warehouse to optimize the flow of materials, products, and workers. A well-designed warehouse layout can significantly improve the efficiency and productivity of a warehouse operation by reducing the time and effort required to move items from one location to another.By optimizing the warehouse layout, businesses can reduce material handling costs, minimize travel time and distances, and improve safety for workers. A well-designed warehouse layout can also support future growth and expansion of the business.

Here we will talk about warehouse layout patterns, how to design warehouse layouts, and warehouse layout tips.

II. General Types of Warehouse Layout Pattern

Improving the layout of your warehouse can have a significant impact on the efficiency and productivity of warehouse operations. While there's no one-size-fits-all solution, there are some standard design options that can serve as a great starting point. Keep in mind that every warehouse is unique and requires tailored solutions, but these base options can be a good fit for many facilities.There are 3 common warehouse layout patterns:

1. U-shaped design

In a U-shaped layout, workstations and equipment are arranged in a U-shape configuration, with products and materials flowing through the open end of the U. The main advantage of this layout is that it allows for a continuous flow of goods through the warehouse, while also enabling efficient use of space. This layout is particularly useful for businesses that require a high level of flexibility and adaptability, as it allows for easy reconfiguration of the workspace.

The U-shaped layout provides maximum flexibility and adaptability compared to the other two patterns. This layout is ideal for businesses that need to handle a wide variety of products and processes. However, the U-shaped layout can also present some challenges. It can be more difficult to manage traffic flow and congestion at the open end of the U-shape, and it can also be challenging to balance the workload between workstations. In addition, this layout can be less efficient for businesses that have a high-volume of products with similar processes, as it may not allow for as efficient a flow of goods as the I-shaped layout.

2. L-shaped design

In an L-shaped layout, workstations and equipment are arranged in an L-shape configuration. The main advantage of this layout is that it allows for the efficient use of space and enables a continuous flow of goods through the warehouse. This layout is particularly useful for businesses that have a limited amount of space but need to handle a high volume of products.

The L-shaped layout provides more flexibility and adaptability compared to the I-shaped layout. The open corner of the L-shape can be used for other functions such as an office, break room, or storage area. However, the L-shaped layout can also present some challenges. It can be more difficult to manage traffic flow and congestion in the elbow of the L-shape, and it can also be challenging to balance the workload between workstations. In addition, this layout can limit the flexibility and adaptability of the workspace, particularly if the warehouse needs to be reconfigured in the future.

3.I-shaped design

The I-shaped layout is the most common and straightforward warehouse layout pattern. In this layout, workstations and equipment are arranged in a straight line along the length of the warehouse. Products and materials flow along the line in a linear fashion, moving from one workstation to the next. This layout is useful for businesses that have a high-volume of products with similar processes, as it allows for an efficient and continuous flow of goods.

One of the main advantages of the I-shaped layout is its simplicity, which makes it easy to design and implement. This layout is also efficient in terms of space utilization, as it minimizes the need for aisle space. However, the I-shaped layout can also present some challenges. It can be difficult to manage traffic flow and congestion, as well as to balance the workload between workstations. In addition, this layout can be inefficient for businesses that require more complex processes, as it can limit the flexibility and adaptability of the workspace.

III. How To Design Warehouse Layout

1. Gather InformationCollect information about the products, materials, and equipment that will be stored and processed in the warehouse. This includes information about the size, weight, and shape of the products, as well as any special storage or processing requirements.

2. Determine Space Requirements

Calculate the total space required for storage, processing, and other activities. This includes the space required for equipment, workstations, aisles, and storage racks.

3. Analyze Flow Patterns

Analyze the flow patterns of products and materials through the warehouse, including the movement of goods from receiving to storage to shipping.

4. Select Layout Type

Select a warehouse layout type based on the specific needs and requirements of the business, as well as the size and shape of the available space.

5. Develop a Layout Plan

Develop a preliminary layout plan that includes the placement of equipment, workstations, storage racks, and other features of the warehouse.

6. Test the Layout

Test the layout by simulating the movement of goods through the warehouse and identifying any potential bottlenecks or issues.

7. Revise the Layout

Revise the layout based on the results of testing and feedback from stakeholders, and create a final layout plan.

8. Implement the Layout

Implement the final layout plan by installing equipment, setting up workstations, and arranging storage racks and other features of the warehouse.

IV. Warehouse Layout Tips

As the backbone of any supply chain operation, warehouses must be designed and organized to maximize efficiency and productivity. A well-planned warehouse layout can help streamline operations, minimize downtime, and reduce overall costs. Here are some essential warehouse layout tips to consider:1. Space loading and unloading areas properly

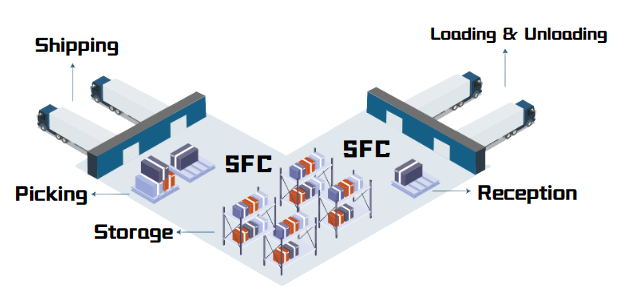

The loading and unloading area is a critical component of any warehouse. Ensure that there is enough space to accommodate the volume of goods that will be coming in and going out of the warehouse. It is common to space loading and unloading areas out and by providing ample space, you can reduce the risk of accidents and improve turnaround times.

2. Separate the Reception Area

Separating the reception area from the main warehouse floor can help prevent congestion and ensure that incoming shipments are processed efficiently. Consider setting up a separate area for inspection and quality control.

3. Organize the Storage Area

Proper organization of the storage area is crucial for maximizing storage capacity and minimizing the risk of damage or loss. Use racking systems and shelves to make the most of vertical space and implement an efficient labelling system to make it easier to find items.

4. Adopt lean inventory practices

Adopting a lean inventory system can help reduce waste and improve efficiency. By using just-in-time inventory management, you can reduce the amount of inventory on hand and minimize the space required for storage.

5. Prioritize safety

Safety should always be a top priority in the warehouse. Make sure that your layout takes into account potential hazards, such as forklift traffic or areas with low visibility. Use signage, markings, and barriers to clearly indicate safe pathways and work zones.

When it comes to warehouse safety, implementing a comprehensive Warehouse Security Checklist and taking it into regular action is essential. This checklist should include measures such as installing Warehouse Security Cameras, ensuring proper warehouse lighting, implementing an alarm system, developing a Warehouse Emergency Response Plan, conducting regular security patrols, implementing an Access Control System, and having secure Entryway Security Doors and Window Security.

In conclusion, organizing your warehouse layout is crucial for improving the efficiency of your fulfillment operations and maximizing your available space. By following the tips and guidelines mentioned in this blog, you can optimize the layout of warehouse for your specific business needs and create a safe and productive environment for your employees. Remember to regularly review and update your layout to accommodate changes in your inventory and business operations. With careful planning and implementation, you can transform your warehouse into a well-organized and streamlined distribution center.

Post Views:16292

Post Views:16292

Copyright statement: The copyright of this article belongs to the original author. Please indicate the source for reprinting.

Previous Post

Case Study: Why Rolling Square Choose SFC For 8 Years

Next Post

TAGS

Hot Research

Get Custom eCommerce Fulfillment Service

Book a Meeting

Get a Custom China Fulfillment Solution with FREE Storage for 30 Days

Want to know about our services, fees or receive a custom quote?

Want to know about our services, fees or receive a custom quote?

Please fill out the form on the right and we will get back to you within a business day.

Please fill out the form on the right and we will get back to you within a business day.

The more information you provide, the better our initial response

will be.

The more information you provide, the better our initial response

will be.

TAGS:

TAGS: