Table of Contents

What Is an Inventory Management System? A Complete Guide for eCommerce & 3PL

Time: Aug 21,2025 Author: SFC Source: www.sendfromchina.com

Every successful e-commerce or logistics business knows that inventory is both its greatest asset and its biggest liability. An Inventory Management System (IMS) acts as the vital nerve center that ensures goods move precisely where they're needed, when they’re needed—and at the right cost. It’s not just software; it’s a structured, data-driven approach that tracks stock from purchase through point-of-sale, dramatically reducing waste and stockouts.

In this guide, we’ll walk through everything you need to know about inventory management systems—from how they work and why they matter, to the methods, challenges, and strategies that distinguish efficient operations in today’s dynamic supply chain landscape. Let’s dive in.

1. What Is an Inventory Management System

Picture this: you’re running an e-commerce operation, juggling stock across warehouses, trying not to oversell—or drown in unsold items. An Inventory Management System is your backbone. It’s the process—and increasingly, the software—that helps you track, control, and optimize the whole lifecycle of goods, from receipt to dispatch.In simple terms, an IMS enables businesses to monitor inventory levels, know where items are located, predict when to reorder, and reduce waste. It bridges procurement, warehousing, and fulfillment. Whether you still rely on spreadsheets or use cloud-based software, the goal remains the same: slim operations, solid margins.

2. Why Inventory Management System Matters for eCommerce Businesses

In the fast-paced realm of eCommerce, an Inventory Management System (IMS) is far more than a tool—it’s the heartbeat of your operations. From boosting profits to elevating customer trust, here’s why a robust IMS is critical.

Reduce Errors, Save Costs, Improve Margins

Human errors—miscounts, misplaced items, or typos—can erode nearly 7–10% of profit margins for online retailers. An IMS automates tracking and conversion, significantly reducing these risks. It also minimizes the costs tied up in both overstocking and stockouts, helping businesses sidestep deadstock and disappointing sale opportunities.Real-Time Visibility Enables Smarter Decisions

IMS platforms grant a unified, real-time view of stock across locations and sales channels. That means accurate forecasting, automatic reorder alerts, and better safety stock planning—all steering you toward leaner and smarter operations.Scale Without Chaos

Growth brings complexity. An IMS enables you to add new products, warehouses, and platforms with confidence—without breaking your workflows or overloading your team. This flexibility lets businesses scale on autopilot instead of scaling headaches.Order Fulfillment That Customers Love

Customers expect precision and timing. An IMS helps you deliver both—ensuring accurate availability, faster picking, and on-time shipping. That translates directly into a better shopping experience and more repeat customers.Boost Customer Loyalty and Trust

When customers confidently place orders knowing items are in stock—and they arrive on time—their trust in your brand grows. Delays, mismatches, or cancellations are loyalty killers; an IMS helps you avoid them.Elevate Supplier Relationships

An IMS enables timely, data-driven supplier engagements. Accurate reorder points, paired with historical data, improve forecasting and foster reliability—making you a preferred partner rather than a sporadic buyer.Master Multichannel Execution

Whether you're selling on Shopify, Amazon, or your own site, IMS ensures real-time stock sync across all channels. This omnichannel harmony prevents double-sells, miscommunication, and inventory friction.Future-Proof with Real-Time Adaptivity

IMS isn’t just about record-keeping—it lets you react swiftly to market changes. Trends, seasonal surges, or supply hiccups? You can pivot with real-time strategies, supported by system visibility.Unlock Working Capital Efficiency

Inventory represents significant working capital. IMS empowers better Days Inventory Outstanding (DIO) management, turning idle stock into cash flow—and enabling smarter investments. Leaner Ops through Forecast Automation AI-powered IMS—like the one used by Amarra, a global dress distributor—can slash overstock by 40%, ensuring the right amount of stock and no more.3. Features of Inventory Management Systems

Your inventory management system isn’t just a digital warehouse notebook—it’s a powerhouse of precision, automation, and insight. To stand out, especially for e-commerce and 3PL players like SendFromChina, an IMS must offer a layered suite of capabilities targeting visibility, efficiency, forecasting, and seamless integration. Here’s an enhanced breakdown of what such a system should include:

Core Functionalities

Real-time Inventory Tracking: Track stock levels, movements, and allocations instantly—whether stock is sold, transferred, or received, the system updates without delay. Essential for avoiding overselling or stockouts.Reorder Points & Low-Stock Alerts: Automatically flag items when they fall below pre-set thresholds. Some IMS take this further by considering supplier lead times, ensuring timely replenishment.

Purchase & Supplier Management Integration: Generate POs effortlessly, manage vendor details and histories, and reference past performance for smarter purchasing decisions. This centralizes operations and reduces manual effort.

Multi-Location Support: Track inventory across multiple warehouses or geographic locations in real time. Supports inter-location transfers and gives unified reporting—for consistent customer experience regardless of storage location.

Identity, Traceability & Item-level Control

Product Identification (Barcodes, RFID, QR, NFC): Labels and scanners (barcode, RFID, or QR codes) ensure swift item identification and accurate transaction logging. This reduces mistakes and accelerates warehouse operations.Batch & Serial Number Tracking: Track items at the granular level—whether by batch (critical for perishable goods or recall readiness) or serial number (vital for warranties, high-value items, or after-sales support).

Unlimited SKUs & Scalability: Your IMS must grow with your inventory—without unfair SKU limits, transaction caps, or vendor restrictions. Scalability sets the foundation for long-term expansion.

Demand & Forecasting Intelligence

Inventory Optimization & Forecasting: Modern systems use rules and algorithms to calculate reorder points, appropriate order quantities, and lead time demand—helping prevent overstock and understock.AI-Powered Demand Planning: As seen at major retailers like Walmart and Target, AI enhances precision by identifying patterns, predicting shortages, and even suggesting location-specific stocking—shifting IMS from reactive to proactive.

Order Fulfillment & Warehouse Efficiency

Order Management (Pick, Pack, Dispatch): Streamline fulfillment via flexible picking workflows, partial shipments, and international shipping standard codes—key for high-performance logistics.Stocktake & Cycle Counting Support: Built-in tools for streamlined audits—counting by location or product, adjusting discrepancies, and reporting variances to preserve data accuracy and reduce stock loss.

Integration & Access

ERP / Financial Software Integration: Syncs seamlessly with tools like QuickBooks or Xero—keeping accounting, inventory, and operations aligned in real time.Sales Channel & 3PL Integration: Connect to e-commerce platforms, POS systems, and 3PL partners for real-time visibility across all touchpoints—helpful for creating a unified inventory experience.

API & Third-Party System Compatibility: Ensure interoperability with CRM, shipping, or custom apps. Strong integrations reduce friction and support system flexibility.

Analytics, Reporting & Insights

Reporting & Business Intelligence: Generate actionable reports on sales per SKU, turnover rates, aging stock, margin analysis, and more—for strategic insight and bottleneck spotting.Advanced Analytics & Predictive Insights: Use dashboards or BI modules that surface performance metrics and predict trends—empowering decision-makers with clarity.

Security & Mobility

Mobile & Scalable Access: Allow warehouse or field staff to scan and manage inventory using mobile devices—perfect for on-the-go updates and decentralized workflows.Data Security & Permissions: Modern IMS offers secure access controls, encryption, and multi-factor authentication—making sure data stays safe and only accessible to authorized users.

4. Pros and Cons of Inventory Management System

Implementing an Inventory Management System can be transformative—enhancing accuracy, efficiency, and visibility—but it's crucial to weigh the advantages against the limitations, especially in dynamic environments like e-commerce and third-party logistics.Pros of Inventory Management System

Efficiency & Accuracy

Automated tracking dramatically cuts down on manual data entry and human error. Real-time updates ensure your stock levels reflect actual conditions, minimizing discrepancies. This is especially powerful when integrated with scanning tools or POS systems.Real-Time Visibility & Reordering

IMS platforms deliver instant data on your inventory, enabling timely ordering and preventing both stockouts and overstock. Automated reorder triggers based on thresholds further streamline replenishment.Operational Cost Savings

By optimizing stock levels, businesses can cut down storage expenses and reduce waste from unsold or obsolete inventory. Over time, accurate forecasting helps maintain leaner operations.Streamlined Order Fulfillment

From picking to dispatch, IMS improves your processing pipeline. This enhances customer satisfaction by reducing delays and ensuring accuracy in orders.Data-Driven Decision Making

Comprehensive reporting—covering turnover rates, demand patterns, and SKU performance—equips you with the insights needed to make strategic inventory, purchasing, and staffing decisions.Enhanced Supplier Management

Forecasting accuracy translates to smarter communication with suppliers, improved lead-time management, and better negotiation leverage.Cloud-Based Access & Integration

Modern systems allow access from anywhere—ideal for hybrid teams and distributed operations. Plus, many IMS integrate with accounting platforms, ERP systems, e-commerce channels, and 3PL networks for seamless coordination.Security & User Controls

IMS often come with role-based permissions, audit logs, and encryption, helping protect sensitive data and ensure compliance.Cons of Inventory Management System

High Implementation & Maintenance Costs

Investing in software, hardware, training, and integration can be substantial—especially for small or mid-sized businesses. Ongoing maintenance and support costs also add up.Complexity & Learning Curve

Advanced systems require time and resources to master. Technical complexity may burden staff and slow adoption, particularly without robust onboarding support.Dependence on Technology

System failures, power outages, or software bugs can cause operational disruptions. Backup procedures and contingency plans remain essential.Security Vulnerabilities

Digital systems are attractive targets for cyberattacks. Risks like data breaches, unauthorized access, or malware necessitate strong cybersecurity defenses.Overreliance on Automation

Automation might lead to reduced physical audits, which can mask issues such as theft, breakage, or misplacements—sometimes resulting in “phantom inventory.”Integration & Customization Challenges

Aligning IMS with legacy systems (e.g., ERP, CRM) can be complex. Off-the-shelf solutions might not perfectly match operational workflows, and further customization can be costly.Scalability Constraints

Some systems may struggle to keep up as business complexity grows—whether through SKU volume, added locations, or expanding fulfillment methods. This can lead to performance bottlenecks.Persistent Operational Risks

Despite high-tech tracking, issues like damaged goods, supplier delays, or poor-quality inventory still pose threats. Systems don’t eliminate these risks—they help manage visibility.5. What Are the Inventory Management Methods

Inventory management is far more than tallying stock—it’s a strategic discipline built on methods tailored to control costs, boost efficiency, and respond to demand. Let’s explore the main approaches businesses rely on to keep their supplies synchronized:

Just-In-Time (JIT)

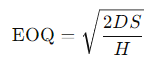

This lean method aims to minimize holding costs by receiving inventory only as it is needed for production or sale. Toyota popularized the JIT approach, and it remains vital for industries like manufacturing and automotive, where space and waste are crucial concerns. Key benefits include reduced storage costs and greater responsiveness, but it hinges on precise demand forecasting and highly reliable suppliers. Any disruption in the supply chain can cause serious delays.Economic Order Quantity (EOQ)

EOQ is a mathematical formula designed to identify the optimal order quantity that minimizes the sum of ordering and holding costs. The classic formula is:

Where:

- D = annual demand

- S = cost per order

- H = holding cost per unit per year

EOQ works best under stable demand and cost conditions, and is most effective when integrated into inventory software for large SKU volumes.

ABC Analysis

ABC divides inventory into three categories based on value and usage frequency:- A-items: High-value, low-volume—tightly monitored.

- B-items: Moderate value and movement.

- C-items: Low-value, high-volume—simplified control.

By focusing attention and resources proportionally, businesses can boost control while reducing management overhead.

Material Requirements Planning (MRP)

MRP translates production goals into inventory requisites using bills of materials (BOMs), current stock levels, and lead times. It’s invaluable in manufacturing, ensuring subcomponents arrive exactly when needed, thereby reducing delays and overstock. However, MRP requires accurate data—errors in demand or BOMs can ripple through operations.Perpetual vs. Periodic Inventory Systems

Perpetual Systems: Provide real-time tracking via scanners or POS systems. This ensures immediate visibility and syncs with financial systems. Still, physical counts remain necessary to catch issues like theft or mis-scanning.Periodic Systems: Rely on scheduled physical inventory counts (e.g., monthly or quarterly). They're more affordable and easier to implement but lack real-time accuracy and are time-intensive.

Vendor-Managed Inventory (VMI)

VMI shifts replenishment responsibility to suppliers, who monitor and restock items based on agreed thresholds and actual usage data. This reduces stockouts, improves lead times, and strengthens supply chain collaboration.Safety Stock & Reorder Point Models

Safety Stock: A buffer against demand spikes or supply delays. Calculations vary—from simple coverage days to forecasts adjusted for variability and service level targets.Reorder Points: Determined by lead time and average demand—these thresholds trigger replenishment before stock runs out.

These models serve as guardrails, ensuring smoother operations despite uncertainty.

Additional Methods: VED Analysis & FSN Classification

VED Analysis: Prioritizes inventory based on criticality—Vital, Essential, or Desirable. Often used for maintenance parts where unavailability has severe consequences.FSN Classification: Segments items as Fast-moving, Slow-moving, or Non-moving—helpful in reducing obsolescence risk and optimizing turnover.

These approaches are pivotal for industries managing diverse inventory types, such as manufacturing or maintenance services.

6. Types of Inventory Management Systems

Inventory management systems come in many forms—ranging from low-tech, manual solutions to advanced, automated platforms. The right choice depends on your scale, industry, and operational complexity. Here’s a breakdown:

Manual Inventory Systems

The simplest form involves counting and logging inventory by hand—on paper or spreadsheets. Favored by micro or startup-level businesses, this method is cost-effective but labor-intensive and error-prone as operations grow.Periodic Inventory Systems

This method uses scheduled physical counts—typically weekly, monthly, or quarterly—to update inventory records. It’s budget-friendly and easy to implement, but lacks real-time visibility and can result in discrepancies or "phantom stock."Perpetual Inventory Systems

These are real-time tracking solutions using POS, barcode scanning, or RFID. Inventory levels adjust immediately after each transaction, offering high accuracy and visibility. Although costlier to implement, they’re ideal for businesses with high turnover.Barcode-Based Systems

A popular automated system where each item is tagged with a barcode scanned during inbound, outbound, or internal movement. This supports perpetual inventory methods and boosts accuracy by reducing manual entry errors.RFID-Based Systems

RFID tags offer advanced tracking with no line-of-sight scanning and fast, simultaneous reads. Especially effective for large warehouses and complex supply chains, though setup costs (tags, readers) are higher.Hybrid Systems

These combine manual and automated elements. Companies may start with simple barcode systems and later integrate cloud-based tools or RFID as they scale. Hybrid systems offer flexibility and gradual investment.Cloud-Based Inventory Systems

Hosted off-site and accessible via internet, these systems offer scalability, remote access, and easy integration with e-commerce, accounting, and analytics tools. Many include AI-driven demand forecasting features.Material Requirements Planning (MRP) Systems

Used in manufacturing, MRP systems calculate inventory needs based on production schedules, bills of materials, and lead times—optimizing orders and reducing production delays. Implementation can be complex and costly.Just-In-Time (JIT) Systems

A lean inventory model that minimizes holding costs by ordering stock only when needed. It works well for high-turnover environments but makes businesses vulnerable to supply chain disruptions.Partnerized Inventory Management (PIM)

This model addresses long-tail, slow-moving inventory—such as spare parts for discontinued products—by keeping items on hand in a partner or shared market setup, instead of scrapping or discarding them.Warehouse Execution Systems (WES) & Automated Storage/Retrieval (AS/RS)

- WES: Manages real-time product flows within warehouses—handling tasks like receiving, sorting, replenishment, and shipping using automation and responsive planning logic.- AS/RS: Uses robotics and conveyor systems to automatically store and retrieve items, updating inventory status digitally. This improves space use, turnover speed, and reduces manual labor.

7. How Does an Inventory Management System Work

An Inventory Management System is more than just a digital ledger—it's the backbone of modern supply chains, retail operations, and manufacturing efficiency. Here's how it functions step by step:

Product Data Input

The process begins by entering detailed product information into the system, including:- Product names and descriptions

- Stock Keeping Units (SKUs)

- Supplier details

- Cost and retail prices

- Minimum and maximum stock levels

This foundational data enables accurate tracking and management throughout the product's lifecycle.

Inventory Tracking and Monitoring

As products are received, sold, or used, the IMS updates inventory levels in real-time. Advanced systems utilize technologies like barcode scanning, RFID, or IoT sensors to automate this process, reducing human error and providing up-to-date stock information.Order Management and Fulfillment

When a customer places an order, the IMS:- Verifies stock availability

- Allocates inventory

- Generates picking lists

- Coordinates packing and shipping

This ensures timely and accurate order fulfillment, enhancing customer satisfaction.

Replenishment and Procurement

To prevent stockouts, the IMS monitors inventory levels and triggers reorder alerts when stock falls below predefined thresholds. Some systems automate the creation of purchase orders, streamlining the procurement process and maintaining optimal inventory levels.Reporting and Analytics

Modern IMS platforms provide robust reporting tools that offer insights into:- Sales trends

- Inventory turnover rates

- Stock aging

- Supplier performance

These analytics assist in strategic decision-making, demand forecasting, and identifying areas for improvement.

8. Challenges in Inventory Management

Even with the best tools and methods, hurdles persist:- Data accuracy risks: Mislabeling, lost items, inaccurately scanned goods can throw system counts off.

- High initial investment: ERP or AI-rich systems tip budgets, and training takes time.

- System failure risks: Downtime—power or connectivity outages—can stall operations.

- Complexity mismatch: Over-engineering for a small business, or under-sophisticated solutions for growing operations, both hurt efficiency.

- Supplier reliability: Especially for JIT, any supplier delays ripples through and can lead to stockouts.

So, a wise business builds redundancy, trains staff well, and picks systems to match real needs—not hype.

9. Conclusion

An Inventory Management System, when thoughtfully chosen and implemented, is more than software—it’s the backbone of modern e-commerce and logistics efficiency. From basic spreadsheet tracking to AI-driven, cloud-based systems, the right solutions bring accuracy, speed, and visibility—unlocking cost savings and customer satisfaction.For a third-party logistics provider like SendFromChina, a robust IMS isn’t optional—it’s strategic. It ensures clients’ goods move seamlessly across borders and warehouses, reorder cycles are smartly managed, and nothing gets lost in translation (or transit). Choose wisely, implement carefully, and the system becomes your competitive edge.

10. FAQs

1. What is the simplest form of inventory management?

Using a spreadsheet (e.g. Excel or Google Sheets) to manually log quantities and movements—it’s basic and best suited for very small operations.2. What’s the difference between perpetual and periodic inventory systems?

Perpetual systems update stock levels in real time via connected software or scanners. Periodic systems rely on manual counts at set intervals.3. How does AI improve inventory management?

AI can forecast demand, predict stock shortages, optimize replenishment, and even personalize stock allocation across locations for faster response.4. Is an ERP-based system right for small businesses?

ERP systems offer rich features but come with high cost and complexity. Small businesses may benefit more from cloud-based IMS that grow with volume.5. How often should physical inventory checks happen?

That depends—cycle counting (regular partial checks) is efficient. Full physical counts are usually done quarterly or annually, depending on risk and scale. Post Views:1366

Post Views:1366

Copyright statement: The copyright of this article belongs to the original author. Please indicate the source for reprinting.

Previous Post

August 2025 Logistics Shake-Up: Rising Costs and Policy Shifts Cross-Border Sellers Can’t Ignore

Next Post

What Is Inventory Visibility & Why It’s Crucial for eCommerce

TAGS

Hot Research

Get a Custom China Fulfillment Solution with FREE Storage for 30 Days

Want to know about our services, fees or receive a custom quote?

Want to know about our services, fees or receive a custom quote?

Please fill out the form on the right and we will get back to you within a business day.

Please fill out the form on the right and we will get back to you within a business day.

The more information you provide, the better our initial response

will be.

The more information you provide, the better our initial response

will be.

TAGS:

TAGS: